Chithandizo cha laser pamwamba ndi ukadaulo womwe umagwiritsa ntchito mtengo wapamwamba kwambiri wa laser kuti utenthetse zinthuzo m'njira yosalumikizana, ndikuzindikira kusinthidwa kwake kwapamtunda pogwiritsa ntchito kuzizira kochititsa chidwi kwa zinthuzo.Ndizopindulitsa kukonza makina ndi thupi la zinthu zakuthupi, komanso kukana kuvala, kukana kwa dzimbiri ndi kukana kutopa kwa zigawozo.M'zaka zaposachedwa, matekinoloje opangira laser pamwamba monga kuyeretsa laser, kuzimitsa laser, alloying laser, laser shock kulimbikitsa ndi laser annealing, komanso laser cladding, laser 3D printing, laser electroplating ndi matekinoloje ena opanga ma laser abweretsa mwayi wogwiritsa ntchito. .

1. Kuyeretsa laser

Kuyeretsa kwa laser ndi njira yatsopano yoyeretsera pamwamba yomwe ikukula mwachangu, yomwe imagwiritsa ntchito mtengo wapamwamba kwambiri wa laser kuti iwunikire pamwamba pa chogwiriracho, kuti dothi, tinthu ting'onoting'ono kapena zokutira pamtunda zitha kusungunuka kapena kukulitsa nthawi yomweyo, ndikukwaniritsa njira yoyeretsa. ndi kuyeretsedwa.Kuyeretsa kwa laser kumagawika makamaka pakuchotsa dzimbiri, kuchotsa mafuta, kuchotsa utoto, kuchotsa utoto ndi njira zina;Amagwiritsidwa ntchito makamaka poyeretsa zitsulo, kuyeretsa zotsalira za chikhalidwe, kuyeretsa zomangamanga, ndi zina zotero. Kutengera ntchito zake zonse, kukonza zolondola komanso zosinthika, kugwiritsa ntchito bwino kwambiri komanso kupulumutsa mphamvu, kutetezedwa kwachilengedwe kobiriwira, osawononga gawo lapansi, nzeru, kuyeretsa bwino, chitetezo, kugwiritsa ntchito kwakukulu ndi mawonekedwe ena ndi zabwino zake, zadziwika kwambiri m'mafakitale osiyanasiyana.

Poyerekeza ndi njira zachikhalidwe zoyeretsera monga kuyeretsa makina, kuyeretsa corrosion mankhwala, kuyeretsa madzi olimba kwambiri, kuyeretsa pafupipafupi akupanga, kuyeretsa laser kuli ndi zabwino zake.

2. Laser kuzimitsa

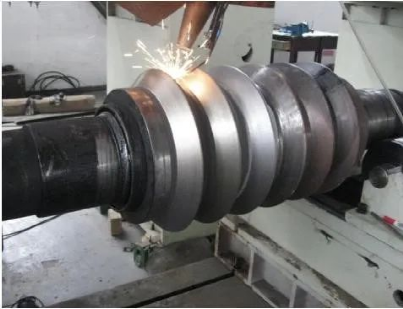

Kuzimitsa kwa laser kumagwiritsa ntchito laser yamphamvu kwambiri ngati gwero la kutentha kuti chitsulo chikhale chotentha komanso chozizira mwachangu.Njira yozimitsira imatsirizidwa nthawi yomweyo kuti mupeze kuuma kwakukulu ndi mawonekedwe apamwamba kwambiri a martensite, kukonza kuuma ndi kuvala kukana kwachitsulo pamwamba pazitsulo, ndikupanga kupanikizika koponderezedwa pamwamba kuti muthe kupirira kutopa.Ubwino waukulu wa njirayi ndi monga madera ang'onoang'ono omwe amakhudzidwa ndi kutentha, kapindika kakang'ono, makina apamwamba kwambiri, kusinthasintha kwabwino kwa kuzimitsa kosankha, kuuma kwakukulu kwa njere zoyengedwa, komanso kuteteza chilengedwe mwanzeru.Mwachitsanzo, malo a laser akhoza kusinthidwa kuti azimitsa malo aliwonse m'lifupi;Kachiwiri, mutu wa laser ndi kulumikizana kwa loboti yamitundu yambiri kumatha kuzimitsa gawo lomwe lasankhidwa la magawo ovuta.Mwachitsanzo, kuzimitsa kwa laser kumakhala kotentha kwambiri komanso kwachangu, ndipo kupsinjika kozimitsa ndi kupunduka kumakhala kochepa.The mapindikidwe workpiece isanayambe kapena itatha laser quenching akhoza pafupifupi kunyalanyazidwa, choncho makamaka oyenera pamwamba mankhwala a mbali ndi zofunika mkulu mwatsatanetsatane.

Pakalipano, kuzimitsa laser kwagwiritsidwa ntchito bwino pakulimbikitsana kwa malo omwe ali pachiopsezo m'makampani a magalimoto, makampani a nkhungu, zida za hardware ndi makampani opanga makina, makamaka popititsa patsogolo moyo wautumiki wa ziwalo zomwe zili pachiwopsezo monga magiya, malo otsetsereka, maupangiri, nsagwada ndi nsagwada. nkhungu.Makhalidwe a laser quenching ndi awa:

(1) Kuzimitsa kwa laser ndi njira yowotchera mwachangu komanso yodzisangalatsa yokha, yomwe sikutanthauza kusungitsa kutentha kwa ng'anjo ndi kuzimitsa koziziritsa.Ndi kuipitsidwa-free, wobiriwira ndi chilengedwe-wochezeka kutentha mankhwala ndondomeko, ndipo mosavuta kukhazikitsa yunifolomu quenching padziko zisamere nkhungu lalikulu;

(2) Monga kuthamanga kwa laser Kutentha kumathamanga, malo omwe amakhudzidwa ndi kutentha ndi ochepa, ndipo kutentha kwapamwamba kumatulutsa kutentha, ndiko kuti, nthawi yomweyo kutentha kwapafupi, kuphulika kwa imfa kumakhala kochepa kwambiri;

(3) Chifukwa chaching'ono chosiyana cha mtanda wa laser, chimakhala ndi kayendedwe kabwino, ndipo chimatha kuzimitsa nkhungu pamwamba pa njira yowunikira;

(4) Kuzama kosanjikiza kwa laser pamwamba quenching nthawi zambiri kumakhala 0.3-1.5 mm.

3. Laser annealing

Laser annealing ndi njira yochizira kutentha yomwe imagwiritsa ntchito laser kutenthetsa zinthu pamwamba, kuwonetsa zinthuzo kutentha kwambiri kwa nthawi yayitali, kenako kuziziziritsa pang'onopang'ono.Cholinga chachikulu cha njirayi ndikumasula kupsinjika, kuonjezera ductility ndi kulimba, ndikupanga microstructure yapadera.Amadziwika ndi kuthekera kosintha mawonekedwe a matrix, kuchepetsa kuuma, kuyeretsa mbewu ndikuchotsa kupsinjika kwamkati.M'zaka zaposachedwa, luso la laser annealing lakhalanso njira yatsopano mumakampani opanga ma semiconductor, omwe amatha kusintha kwambiri kuphatikiza kwa mabwalo ophatikizika.

4. Kulimbitsa mphamvu ya laser

Ukadaulo wolimbitsa ma laser ndi ukadaulo watsopano komanso wapamwamba kwambiri womwe umagwiritsa ntchito mafunde a plasma omwe amapangidwa ndi mtengo wolimba wa laser kuti apititse patsogolo kutopa, kukana kuvala komanso kukana dzimbiri kwazitsulo.Ili ndi zabwino zambiri, monga kusakhudzidwa ndi kutentha, mphamvu zochulukirapo, kuthamanga kwamphamvu kwambiri, kuwongolera mwamphamvu komanso kulimbitsa modabwitsa.Nthawi yomweyo, kulimbitsa kwamphamvu kwa laser kumakhala ndi kupsinjika kwakuya kotsalira kotsalira, mawonekedwe abwino a microstructure ndi kukhulupirika pamwamba, kukhazikika kwamafuta abwino komanso moyo wautali.M'zaka zaposachedwa, ukadaulo uwu wapeza chitukuko chofulumira, ndipo uli ndi gawo lalikulu muzamlengalenga, chitetezo cha dziko ndi makampani ankhondo ndi magawo ena.Komanso, ❖ kuyanika makamaka ntchito kuteteza workpiece kuti laser amayaka ndi kumapangitsanso mayamwidwe laser mphamvu.Pakali pano, zipangizo zokutira zomwe zimagwiritsidwa ntchito kwambiri ndi utoto wakuda ndi zojambulazo za aluminiyamu.

Laser peening (LP), yomwe imadziwikanso kuti laser shock peening (LSP), ndi njira yomwe imagwiritsidwa ntchito popanga uinjiniya wa pamwamba, ndiye kuti, kugwiritsa ntchito matabwa amphamvu kwambiri a laser kuti apange kupsinjika kotsalira muzinthu kuti azitha kukana kuvala. (monga kukana kuvala ndi kukana kutopa) kwa zinthu zakuthupi, kapena kupititsa patsogolo mphamvu ya zigawo zoonda za zinthu kuti zithandizire kuuma kwa zinthu.

Mosiyana ndi ntchito zambiri pokonza zinthu, LSP sagwiritsa ntchito mphamvu ya laser pochiza kutentha kuti ikwaniritse zomwe mukufuna, koma imagwiritsa ntchito mtengo wamakina pokonza makina.Mtengo wapamwamba wa laser umagwiritsidwa ntchito kukhudza pamwamba pa chogwirira ntchito chomwe chili ndi mphamvu yayitali kwambiri.

Kuwala kowala kumakhudza chitsulo chogwirira ntchito, kusungunula chogwiriracho kukhala plasma yopyapyala nthawi yomweyo, ndikuyika kupsinjika kwa mafunde pachogwirirapo ntchito.Nthawi zina wowonda wosanjikiza wa opaque cladding zakuthupi anawonjezera workpiece m'malo zitsulo evaporation.Kuti akanikizire, zida zina zomangira zowonekera kapena zigawo zosokoneza za inertial zimagwiritsidwa ntchito kujambula plasma (nthawi zambiri madzi).

Plasma imapanga kugwedezeka kwa mafunde, imapanganso mawonekedwe ang'onoang'ono amtundu wa chogwirira ntchito pamalo okhudzidwa, kenaka imapanga kachitidwe kakuchulukira kwachitsulo ndikukakamira.Kupanikizika kwakuya komwe kumapangidwa ndi izi kumatha kukulitsa moyo wa gawolo.

5. Laser alloying

Laser alloying ndi luso latsopano pamwamba kusinthidwa, amene angagwiritsidwe ntchito pokonzekera amorphous nanocrystalline analimbitsa cermet gulu zokutira pamwamba pa zigawo structural malinga ndi zinthu zosiyanasiyana utumiki wa zipangizo ndege ndi makhalidwe a mkulu mphamvu kachulukidwe laser mtengo Kutentha ndi condensation mlingo, kotero monga kukwaniritsa cholinga cha kusinthidwa pamwamba pa zipangizo ndege.Poyerekeza ndi ukadaulo wa laser alloying, ukadaulo wa laser cladding uli ndi mawonekedwe ang'onoang'ono a dilution a gawo lapansi mpaka dziwe losungunuka, madera ang'onoang'ono okhudzidwa ndi kutentha, mapindikidwe ang'onoang'ono amafuta a workpiece ndi kuchuluka kwa zidutswa zazing'ono pambuyo pa chithandizo cha laser.Kuyika kwa laser kumatha kusintha kwambiri mawonekedwe a zinthu zakuthambo, ndikukonzanso zida zowonongeka.Ili ndi mawonekedwe achangu kwambiri, kuthamanga mwachangu, chitetezo chachilengedwe chobiriwira komanso chopanda kuipitsa, komanso magwiridwe antchito abwino a workpiece pambuyo pa chithandizo.

Tekinoloje ya laser cladding ndi imodzi mwamaukadaulo atsopano osinthira pamwamba omwe akuyimira njira yachitukuko komanso mulingo waukadaulo wapamwamba.Ukadaulo wa laser cladding wasanduka malo opangira kafukufuku pakusintha kwamtundu wa titaniyamu chifukwa cha zabwino zake zosaipitsa komanso kuphatikiza zitsulo pakati pa zokutira ndi gawo lapansi.Laser cladding ceramic ❖ kuyanika kapena ceramic tinthu analimbitsa gulu ❖ kuyanika ndi njira yabwino kusintha pamwamba kuvala kukana titaniyamu aloyi.Malinga ndi zikhalidwe zenizeni ntchito, kusankha yoyenera dongosolo zinthu, ndi laser cladding luso akhoza kukwaniritsa bwino ndondomeko zofunika.Ukadaulo wa laser cladding umatha kukonza magawo osiyanasiyana olephera, monga masamba a injini ya aeroengine.

Kusiyana pakati pa laser pamwamba alloying ndi laser pamwamba cladding ndi kuti laser pamwamba alloying ndi kusakaniza anawonjezera aloyi zinthu ndi pamwamba wosanjikiza gawo lapansi mu boma madzi kupanga aloyi wosanjikiza;Laser pamwamba cladding ndi kusungunula precoating onse ndi yaying'ono kusungunula gawo lapansi pamwamba, kuti cladding wosanjikiza ndi gawo lapansi zinthu kupanga zitsulo osakaniza ndi kusunga zikuchokera cladding wosanjikiza kwenikweni zosasintha.Ukadaulo wa laser alloying ndi laser cladding umagwiritsidwa ntchito makamaka kuwongolera kukana kuvala pamwamba, kukana dzimbiri komanso kukana kuyika kwa ma aloyi a titaniyamu.

Pakalipano, luso la laser cladding lakhala likugwiritsidwa ntchito kwambiri pokonza ndi kusinthidwa kwazitsulo.Komabe, ngakhale miyambo ya laser cladding ili ndi ubwino ndi makhalidwe a processing osinthasintha, kukonza mawonekedwe apadera, zowonjezera zowonjezera, ndi zina zotero, ntchito yake yogwira ntchito ndiyotsika, ndipo sichingakwaniritse zofunikira za kupanga ndi kukonza mofulumira kwambiri. minda ina yopanga.Pofuna kukwaniritsa zosowa za kupanga misa ndikuwongolera magwiridwe antchito, ukadaulo wa laser cladding wothamanga kwambiri unayamba.

High liwiro laser cladding luso akhoza kuzindikira yaying'ono ndi chilema free cladding wosanjikiza.Maonekedwe a pamwamba a cladding wosanjikiza ndi yaying'ono, yolumikizana ndi zitsulo ndi gawo lapansi, palibe cholakwika chotseguka, ndipo pamwamba ndi yosalala.Sizingatheke kukonzedwa pa thupi lozungulira, komanso pa ndege ndi pamwamba pa zovuta.Kudzera mosalekeza luso kukhathamiritsa, luso luso chimagwiritsidwa ntchito malasha, zitsulo, nsanja m'mphepete mwa nyanja, kupanga mapepala, zipangizo boma, magalimoto, zombo, mafuta, Azazamlengalenga mafakitale, ndi kukhala wobiriwira remanufacturing ndondomeko kuti akhoza m'malo chikhalidwe electroplating luso.

7. Laser chosema

Laser chosema ndi njira yopangira laser yomwe imagwiritsa ntchito ukadaulo wa CNC kuti ipangire mtanda wa laser wamphamvu kwambiri pamwamba pa zinthu, ndipo imagwiritsa ntchito matenthedwe opangidwa ndi laser kuti apange mawonekedwe omveka bwino pazomwe zili pamwamba.The thupi denaturation wa kusungunuka ndi gasification wa zinthu processing pansi walitsa wa laser chosema kungathandize laser chosema kukwaniritsa zolinga processing.Laser chosema ndi kugwiritsa ntchito laser kulemba mawu pa chinthu.Mawu ojambulidwa ndi teknolojiyi alibe nicks, pamwamba pa chinthucho ndi chosalala komanso chophwanyika, ndipo zolembazo sizidzavala.Makhalidwe ake ndi ubwino wake ndi: otetezeka ndi odalirika;Zolondola komanso mosamala, kulondola kumatha kufika 0.02mm;Sungani chitetezo cha chilengedwe ndi zipangizo panthawi yokonza;Liwiro, liwilo chosema molingana ndi zojambula linanena bungwe;Mtengo wotsika, osati malire ndi kuchuluka kwa processing, etc.

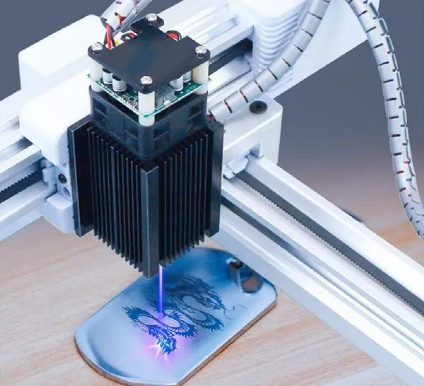

8. Kusindikiza kwa laser 3D

Njirayi imagwiritsa ntchito ukadaulo wa laser cladding, womwe umagwiritsa ntchito laser kuti usungunuke ufa womwe umatengedwa ndi nozzle kuti usungunuke mwachindunji chinthu chosavuta kapena ufa wa aloyi.Pambuyo pa tsinde la laser, madzi a alloy amakhazikika mwachangu kuti azindikire kutulutsa mwachangu kwa alloy.Pakalipano, wakhala akugwiritsidwa ntchito kwambiri popanga mafakitale, kupanga makina, ndege, asilikali, zomangamanga, filimu ndi televizioni, zipangizo zapakhomo, mafakitale a kuwala, mankhwala, zinthu zakale, chikhalidwe ndi luso, zojambulajambula, zodzikongoletsera ndi zina.

9. Chitsanzo mafakitale ntchito laser pamwamba mankhwala ndi remanufacturing

Pakali pano, laser pamwamba mankhwala ndi zina umisiri kupanga, njira ndi zipangizo chimagwiritsidwa ntchito zitsulo, makina migodi, zisamere pachakudya, mphamvu mafuta, zida hardware, njanji mayendedwe, Azamlengalenga, makina ndi mafakitale ena.

10. Kugwiritsa ntchito luso la laser electroplating

Laser electroplating ndi ukadaulo watsopano wopangira mphamvu zamagetsi, womwe ndi wofunikira kwambiri pakupanga ndi kukonza zida za microelectronic ndi mabwalo akuluakulu ophatikizika.Pakadali pano, ngakhale mfundo ya laser electroplating, laser ablation, plasma laser deposition ndi laser jet ikadali pa kafukufuku, matekinoloje awo agwiritsidwa ntchito.Pamene laser mosalekeza kapena kugunda laser irradiates cathode pamwamba mu kusamba electroplating, osati mafunsidwe mlingo wa zitsulo akhoza bwino kwambiri, komanso kompyuta angagwiritsidwe ntchito kulamulira trajectory wa laser mtengo kupeza ❖ kuyanika unshielded wa kuyembekezera zovuta geometry.

Kugwiritsiridwa ntchito kwa laser electroplating pochita kumatengera mikhalidwe iwiri iyi:

(1) Liwiro la dera la kuwala kwa laser ndilokwera kwambiri kuposa liwiro la electroplating m'thupi (pafupifupi nthawi 103);

(2) Kukhoza kulamulira kwa laser ndi kolimba, komwe kungapangitse gawo lofunikira la zinthu kuti liwonjezeke kuchuluka kwazitsulo zofunika.Electroplating wamba imachitika pa gawo lonse la elekitirodi, ndipo liwiro la electroplating ndi pang'onopang'ono, kotero ndizovuta kupanga mapangidwe ovuta komanso abwino.Laser electroplating imatha kusintha mtengo wa laser kukhala kukula kwa micrometer, ndikutsata mosasunthika pakukula kwa micrometer.Pakupanga madera, kukonza madera ndi kuyika kwanuko pazigawo zolumikizira ma microelectronic, mapu amtundu uwu akukhala othandiza kwambiri.

Poyerekeza ndi electroplating wamba, ubwino wake ndi:

(1) Kuthamanga kwachangu, monga laser plating mpaka 1 μ M/s, laser copper plating mpaka 10 μ M/s, laser jet golide plating mpaka 12 μ M/s, laser jet copper plating mpaka 50 μ m/s;

(2) Kuyika kwachitsulo kumangochitika m'dera la kuwala kwa laser, ndipo zokutira zapanyumba zimatha kupezeka popanda miyeso yotchinga, motero kumathandizira kupanga;

(3) ❖ kuyanika ❖ kuyanika bwino kwambiri;

(4) Easy kuzindikira kulamulira basi;

(5) Sungani zitsulo zamtengo wapatali;

(6) Sungani ndalama zothandizira zida ndi nthawi yokonza.

Pamene laser mosalekeza kapena zikhumbo laser irradiates cathode pamwamba mu kusamba electroplating, osati mafunsidwe mlingo wa zitsulo akhoza bwino kwambiri, komanso kompyuta akhoza kulamulira mayendedwe a laser mtengo kupeza ❖ kuyanika unshielded ndi kuyembekezera zovuta. geometry.Ukadaulo watsopano wa laser jet kumatheka electroplating Chili ndi laser kumatheka electroplating luso ndi electroplating njira kupopera mbewu mankhwalawa, kuti laser ndi plating njira akhoza kuwombera pa cathode pamwamba, ndi misa kutengerapo liwiro ndi mofulumira kwambiri kuposa misa kutengerapo liwiro. Kuthamanga kwapang'onopang'ono komwe kumachitika chifukwa cha kuwala kwa laser, motero kumapeza liwiro lokwera kwambiri.

Chitukuko chamtsogolo ndi zatsopano

M'tsogolomu, njira yopangira chithandizo cha laser pamwamba ndi zida zopangira zowonjezera zitha kufotokozedwa mwachidule motere:

·Kuchita bwino kwambiri - kuwongolera bwino kwambiri, kukumana ndi kuchuluka kwachangu kwamakampani amakono;

·Kugwira ntchito kwapamwamba - zida zimakhala ndi ntchito zosiyanasiyana, zokhazikika komanso zoyenera pazogwirira ntchito zosiyanasiyana;

-Nzeru zapamwamba - mulingo wanzeru ukukulirakulira mosalekeza, osachitapo kanthu mwachangu;

· Mtengo wotsika - mtengo wa zida ndi wokhoza kulamuliridwa, ndipo mtengo wazinthu zogulira umachepetsedwa;

·Kusintha mwamakonda - kusinthira mwamakonda zida, ntchito yolondola pambuyo pogulitsa,

·Ndipo kuphatikizira - kuphatikiza ukadaulo wa laser ndi umisiri wachikhalidwe.

Nthawi yotumiza: Sep-17-2022